Lukoil Ecto Diesel helps clean and maintain the engine, injectors, and fuel system. This special product protects against power loss in the engine and also extends the life of your vehicle's engine by creating corrosion resistance. By preventing fuel foaming and avoiding underfilling, Ecto Diesel helps improve driving performance and fuel efficiency.

How does Ecto Diesel help clean and keep the engine, injector, and fuel system clean?

STANDARD TEST PEUGEOT XUD-9 (CEC-F-23-A-01)

Although almost all diesel engines produced today use common-rail direct injection (CRDI) systems, a significant number of distributor injection, indirect injection (IDI) engines remain in service. Therefore, it is important that an additive works effectively in both engine types. In an IDI engine, carbon deposits caused by fuel tend to form around the fuel injector nozzle, especially in the pilot injection phases, causing flow loss.

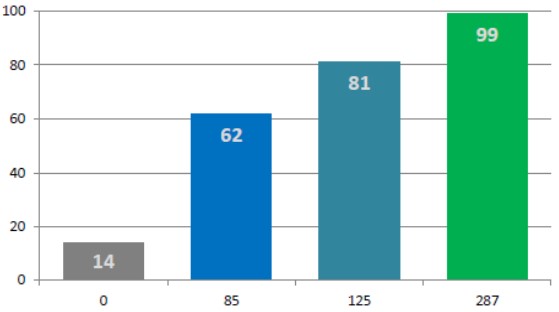

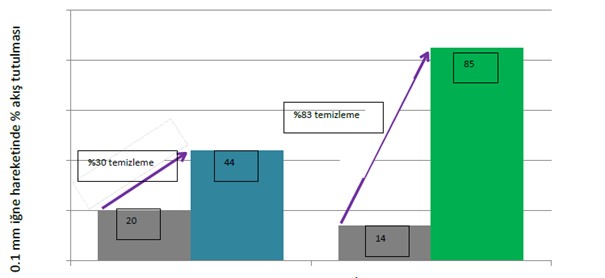

When selected by CEC, XUD9 was considered a good example of the then dominant IDI engine design. Due to its ease of operation and speed, it continues to be widely used. The additive has been comprehensively tested in the Peugeot XUD-9 engine using the official CEC-F-23-A-01 test procedure for both "keep-clean" and "clean-up" performance. The test was carried out with European reference diesel RF79. Testing was conducted at all treat rates to demonstrate additive scalability. Results are graphically shown below:

The approved standard industry test is a keep-clean test that compares flow retention after 10 hours of engine operation using base fuel starting with clean injectors. The test is then repeated, also starting with clean injectors, but this time using the same fuel treated with the additive. It is also possible to modify the test to evaluate cleaning. In this case, the engine is operated for 10 hours on base fuel according to the CEC procedure. The injectors are removed, flow tested, and then reinstalled. The test then continues for another 10 hours on the same batch of diesel fuel, but now treated with the additive.

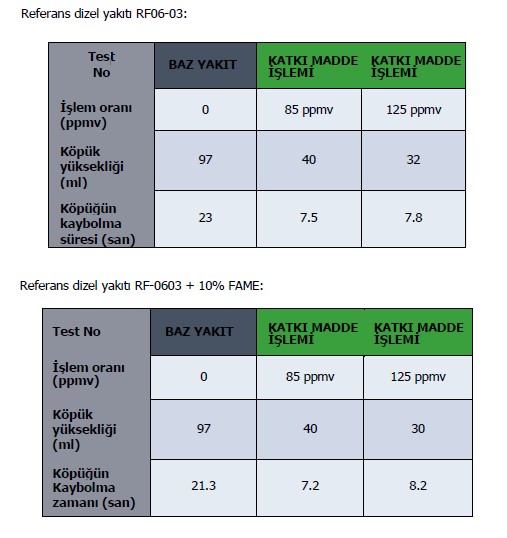

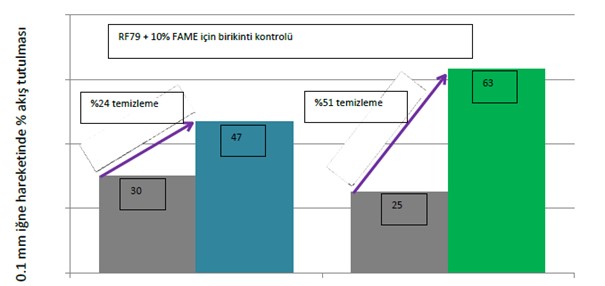

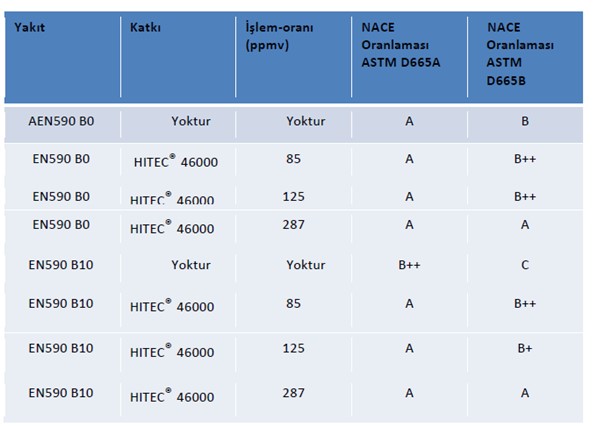

The European market widely uses FAME in diesel, allowed up to 7% in EN590 and up to 10% in EN16734. Therefore, tests have also been carried out with European reference fuel blended with 10% FAME, and the results are shown below:

The original test reports are shown in the appendices: ET XUD9-886 for base fuel; ET XUD9-891 for our treat rate additive.

How does Ecto Diesel protect against power loss in the engine?

STANDARD TEST PEUGEOT DW-10 (CEC-F-A-98-08)

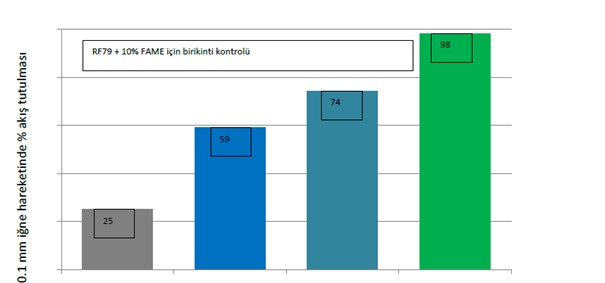

The additive was comprehensively tested in the Peugeot DW-10 engine following the CEC-F-98-A-08 test procedure, for both "keep-clean" and "clean-up" performance. The test was performed using reference diesel RF79 containing 1 ppm zinc.

This test was carried out at recommended treat rate, lower, and higher treat levels to demonstrate scalability.

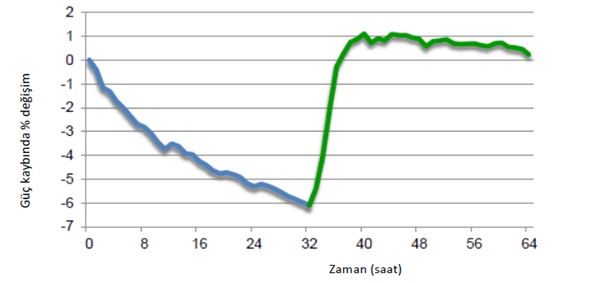

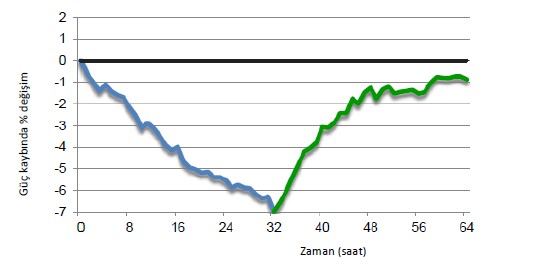

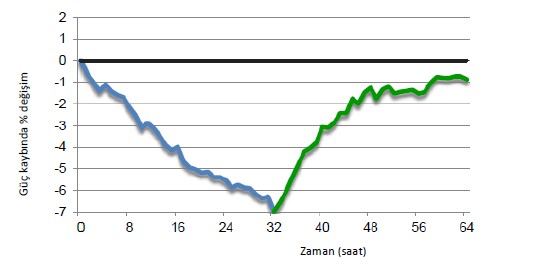

The standard CEC test compares power loss after 32 hours of operation using base fuel with clean injectors. The test is then repeated with the same fuel treated with the additive.

For the clean-up test, the engine is first operated on base fuel for 32 hours. Power loss is recorded, and then the test is repeated for 32 hours, but now with additive-treated fuel.

Results for additive use in both mineral fuel and 10% FAME blend are shown below:

RF79 Reference diesel + 1 ppm Zinc at premium treat-rate clean-up response with additive:

Original test reports shown in the appendices: ET DW10-469/470 referring to experimental additive name DAB3671B03.

RF79 Reference diesel + 1 ppm Zinc at regular treat-rate clean-up response with additive:

Original test reports shown in the appendices: ET DW10-503/504 referring to experimental additive name DAB3897A02.

RF79 Reference diesel + 10% FAME + 1 ppm Zinc at premium treat-rate clean-up response with additive:

How does Ecto Diesel protect against corrosion and extend vehicle life?

Corrosion in a vehicle’s fuel system can cause serious problems. It may lead to leaks in fuel tanks, clog pipelines and filters with rust particles, and affect fuel injection efficiency in severe cases. Even small amounts of water and dissolved air can cause corrosion of metal fuel system components. Additionally, increased use of FAME in diesel raises corrosion concerns.

CORROSION PROTECTION (ASTM D665A / D665B)

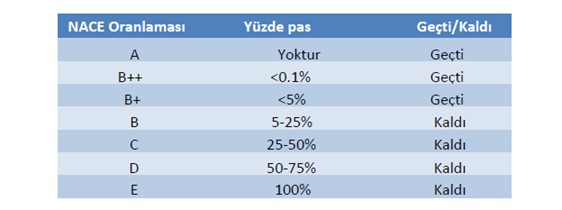

Diesel fuel corrosion characteristics are assessed using a dynamic corrosion test together with a NACE rating scale. ASTM D665A (using distilled water) and ASTM D665B (using synthetic seawater) define the method. 300 ml of diesel fuel and 30 ml of water are stirred at 60°C for up to 24 hours. A steel specimen is immersed in the liquid and then visually rated using the NACE scale below:

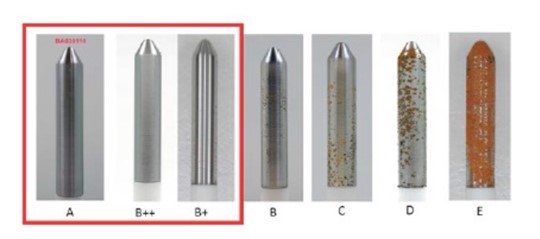

The images below show the visual differences in the NACE rating scale:

The data clearly demonstrates the excellent corrosion prevention performance of the additive.

How does Ecto Diesel prevent fuel foaming and avoid incomplete refueling?

FOAM CONTROL (BNPe NFM-07-075)

All diesel fuels tend to generate foam when pumped into a vehicle tank. Excessive foaming can result in splashing, premature automatic shut-off at the pump, longer refueling time, and environmental concerns from fuel spills. A small amount of anti-foam additive can significantly reduce these issues. Fuel marketers have recognized commercial benefits from allowing higher fill volumes before pump shutoff.

Foam performance can be evaluated using a range of methods from simple hand-shake tests to vehicle refueling trials. However, the industry-recognized test is based on BNPe equipment using the NFM 07-075 procedure. Fuel is injected under pressure into a measuring cylinder and foam height and collapse time are recorded.

The effectiveness of the additive in reducing fuel foaming at different treat rates has been evaluated using the BNPe test equipment shown below:

Diesel fuel anti-foam performance is measured using BNPe equipment according to NFM 07-075, recording foam height and collapse time.

ADDITIVE RESULTS (NFM 07-075)